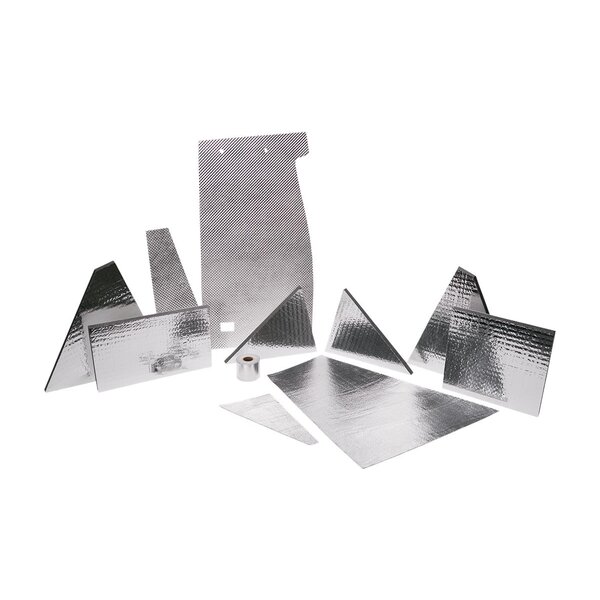

Definition (Featured Snippet): An exhaust heat shield liner is an internal thermal barrier placed inside a heat-shield assembly to reduce heat transfer from hot exhaust components to nearby surfaces. It typically combines a metal facing (aluminum or stainless steel) with a high-temperature insulation layer, and is supplied either adhesive-backed or non-adhesive depending on the retention method.

Metal heat shields alone mainly act as a physical guard and a basic radiant barrier. In demanding exhaust zones—where temperatures cycle rapidly and airflow varies—metal shields can still conduct heat, and the surface temperature of surrounding covers or panels may rise beyond comfort or material limits.

A liner adds a controlled insulation layer inside the heat-shield system, improving thermal resistance without requiring redesign of the entire exhaust layout.

A liner supports heat management by addressing two primary paths:

In practice, the liner functions as a compact “thermal stack-up” that is optimized around limited installation space and real-world vibration.

Aluminum facing is widely used when reflectivity and low mass are priorities. Stainless steel facing is typically selected where durability, abrasion resistance, and corrosion resistance matter more, such as harsh environments or long service intervals.

The insulation layer is chosen by balancing thermal performance against packaging constraints. Key selection factors include available clearance, target temperature reduction, vibration exposure, and the duty cycle (steady cruise vs. frequent idle/stop-start vs. off-road load conditions).

You will see this type of liner in locations where heat needs to be controlled in tight packaging:

If you are sourcing an exhaust heat shield liner kit for OEM/ODM or aftermarket packaging, these parameters accelerate quoting and reduce redesign cycles:

BSTFLEX manufactures high-temperature thermal protection products for automotive and powersports applications. We support custom heat shield liner programs with:

To receive a fast quotation from BSTFLEX, please provide:

Our team will recommend a suitable construction and respond with a quotation promptly.

What is the difference between a heat shield and a heat shield liner?

A heat shield is the outer protective cover. A liner is the internal thermal layer that increases the heat shield system’s thermal resistance and helps reduce outer surface temperature rise.

Is aluminum or stainless steel better for the facing layer?

Aluminum is commonly chosen for reflectivity and low mass. Stainless steel is often selected for durability and resistance to abrasion and corrosion. Selection depends on environment and service life targets.

When should I choose adhesive-backed liners?

Choose adhesive-backed designs when you want simplified placement and faster assembly. Choose non-adhesive designs when mechanical retention is preferred or when removability and rework are important.

Can this be supplied as a custom kit?

Yes. Manufacturers can provide universal sheets or precision die-cut kits based on drawings, templates, or samples.