In today’s automotive industry, automotive heat shield materials are no longer optional components—they are critical elements of vehicle safety, performance, and long-term durability. As engines become more powerful and emissions regulations more demanding, effective thermal management has become a key engineering priority.

This whitepaper-style guide explores advanced automotive heat shield materials, their real-world applications, and how professional material selection can directly impact vehicle reliability and manufacturing efficiency.

Modern vehicles operate under increasingly extreme thermal conditions. Exhaust systems, turbochargers, and catalytic converters regularly reach temperatures exceeding several hundred degrees Celsius. Without reliable automotive heat shield materials, excessive heat can lead to:

Premature failure of plastic and rubber components

Damage to wiring harnesses and fuel systems

Reduced engine efficiency

Increased warranty claims and safety risks

For OEMs and Tier 1 suppliers, investing in the right heat shield solution is not just a technical decision—it is a strategic one.

High-quality automotive heat shield materials must deliver consistent thermal protection under real-world conditions, not just laboratory tests. Professional-grade heat shields are designed to:

Reflect radiant heat away from critical components

Insulate against conductive heat transfer

Maintain structural integrity under vibration and thermal cycling

Resist corrosion, oxidation, and long-term aging

These performance requirements directly influence material selection.

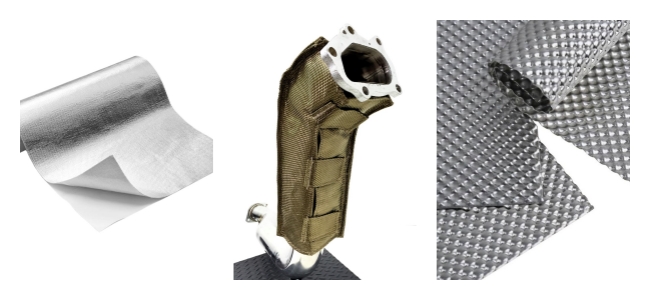

Aluminum remains one of the most popular automotive heat shield materials due to its excellent balance of performance and weight.

Key Performance Benefits:

High heat reflectivity

Lightweight for improved fuel efficiency

Good formability for complex vehicle designs

Typical Applications:

Engine bay heat shields

Underbody thermal protection

Exhaust system outer layers

Aluminum heat shields are frequently combined with insulation layers to enhance overall thermal efficiency.

For high-temperature and high-stress environments, stainless steel offers unmatched durability.

Key Performance Benefits:

Excellent resistance to extreme heat

High mechanical strength

Long service life in harsh environments

Typical Applications:

Turbocharger heat shields

Exhaust manifolds

Catalytic converter protection

Stainless steel automotive heat shield materials are ideal for areas requiring maximum thermal and structural stability.

Insulation materials play a crucial role in advanced heat shield systems.

Key Performance Benefits:

Low thermal conductivity

High temperature tolerance

Flexible integration into multi-layer designs

Typical Applications:

Exhaust wrap insulation

Heat shield cores

Engine compartment insulation pads

Ceramic fiber insulation can withstand temperatures exceeding 1000°C, making it suitable for demanding automotive applications.

To meet modern vehicle requirements, many manufacturers now prefer composite automotive heat shield materials.

A typical structure includes:

A reflective metal outer layer

A high-temperature insulating core

Advantages of Composite Heat Shields:

Superior thermal performance

Reduced weight

Improved vibration resistance

Longer service life

These solutions are widely adopted in advanced exhaust and underbody thermal management systems.

Aluminum reflective shields with insulation backing

Designed to protect electronics, hoses, and plastic parts

Stainless steel or aluminum with ceramic insulation

Designed for continuous high-temperature exposure

Lightweight composite heat shield materials

Prevent heat transfer to the vehicle interior

Many heat shield failures occur not because of poor materials, but because of incorrect material selection or structural design. Professional automotive heat shield material solutions consider:

Actual operating temperatures

Installation environment and airflow

Vibration and mechanical stress

Long-term durability requirements

A properly engineered heat shield system reduces maintenance costs, improves vehicle safety, and enhances brand reputation.

If you are developing or upgrading automotive thermal protection systems, working with an experienced heat shield material supplier gives you a competitive advantage.

We offer:

Customized automotive heat shield material solutions

Support for OEM and Tier 1 applications

Material selection based on real-world performance

Consistent quality and reliable supply