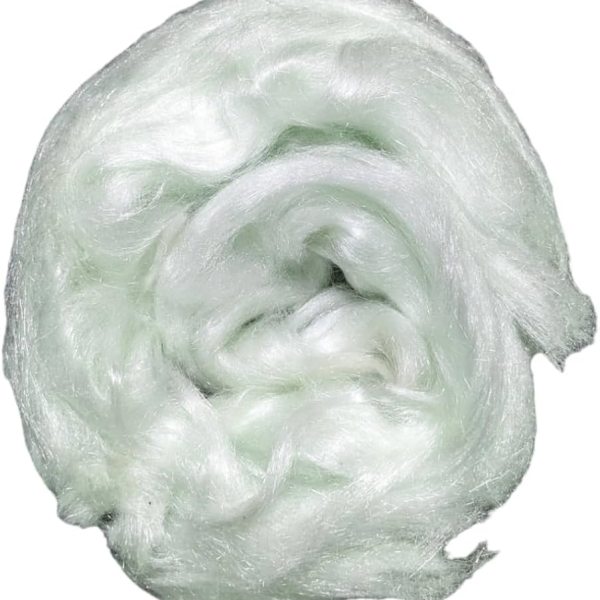

When a silencer becomes louder, develops a harsh rasp, or loses its smooth tone, the root cause is often packing degradation rather than shell damage. High temperature muffler insulation wool is the thermal-acoustic medium inside repackable mufflers and silencers. It reduces noise, helps stabilize exhaust behavior, and can reduce internal hot spots when installed correctly.

This guide is built for buyers, mechanics, performance shops, and OEM teams who want longer service life, fewer repacks, and fewer complaints—especially for performance motorcycles, off-road vehicles, turbo systems, generators, and industrial exhaust lines.

Many suppliers label everything as “exhaust wool.” In real applications, high-temperature performance depends on four practical factors:

1) Heat exposure at the perforated core

Localized temperatures near the core can be far higher than what you measure on the outer shell. Packing typically fails at the core interface first.

2) Pulsation and turbulence

High RPM and short-can designs create strong gas pulses that erode fibers and push them through perforations.

3) Moisture and contamination

Oil vapor or condensate can collapse fiber structure and reduce acoustic absorption.

4) Packing architecture

Durability is often determined by the build, not one single material. In many repackable silencers, a layered system (core wrap + primary packing) lasts longer than a single-material fill.

Fiberglass mat packing is widely used because it installs cleanly and provides stable sound absorption for common street applications.

Best for: street motorcycles, daily drivers, typical automotive repacks

Watch-outs: shorter life in high pulsation or very high heat unless the core is protected

Basalt packing is commonly selected when temperatures exceed standard fiberglass comfort zones. It tends to maintain structure better under heat and is a strong choice for demanding performance conditions.

Best for: performance systems, off-road vibration environments, longer repack intervals

Watch-outs: avoid over-compression; excessive density reduces acoustic efficiency

Ceramic packing is typically used where temperatures are consistently extreme and standard fibers degrade rapidly.

Best for: extreme temperature exposure, steady-state industrial duty cycles

Watch-outs: confirm the form factor (mat vs. bulk fill) required by your silencer design

If your failure mode is “packing blows out too fast,” the fix is often not switching the primary packing alone. The most effective durability upgrade is adding stainless steel wool core wrap around the perforated tube.

What core wrap does:

reduces fiber migration through perforations

slows erosion under turbulence

stabilizes sound and performance longer between repacks

If you want a practical decision framework:

Street / daily use: fiberglass packing mat

High heat / performance / off-road: basalt packing (or ceramic for extreme duty)

If blowout is common: stainless steel wool core wrap first, then install the primary packing

This layered approach addresses the most common complaint: “It got loud again too soon.”

1) Protect the core first

Wrap the perforated tube with stainless steel wool core wrap where applicable before installing the main packing. This is often the single most effective step for extending service life.

2) Maintain even thickness

Uneven packing creates hot spots and weak acoustic zones, reducing durability and sound control.

3) Avoid over-compression

Over-compression reduces the void structure that absorbs sound energy, and it accelerates packing collapse.

4) Match packing style to the muffler design

Mat packing: consistent thickness and clean installation

Pillow inserts: fast service for certain geometries

Bulk fill: use only when the design is intended for it

1) What is high temperature muffler insulation wool used for?

It is used as a thermal-acoustic packing medium inside repackable mufflers and silencers to reduce noise, stabilize exhaust behavior, and help manage heat concentration near the core.

2) Which material lasts longer: fiberglass, basalt, ceramic, or stainless wool?

Service life depends on heat, pulsation, and installation density. In many repackable silencers, the most durable setup is stainless steel wool core wrap + a primary packing (fiberglass, basalt, or ceramic), rather than relying on a single material alone.

3) Can stainless steel wool be used as the only packing?

In some designs, yes. However, many applications use stainless wool as a protective layer to prevent blowout while using a primary acoustic packing for better sound absorption.

4) When should a muffler be repacked?

Common triggers include a louder exhaust, harsher high-frequency tone, or visible fiber loss. Service intervals vary by RPM, vibration, moisture exposure, and muffler construction.

5) What is the most common installation mistake?

Two issues cause most premature failures: over-compressing the packing and skipping core protection.

If you are sourcing high temperature muffler insulation wool or building a repack kit for your market, BSTFLEX can support fiberglass, basalt, ceramic packing options plus stainless steel wool core wrap solutions for durability-focused builds.

Send your application details (engine type, muffler core diameter and length, operating temperature range, and target sound reduction). We will recommend the best packing architecture and supply format (mat, pillow, roll, or bulk) for your production or aftermarket needs.

Mots clés :