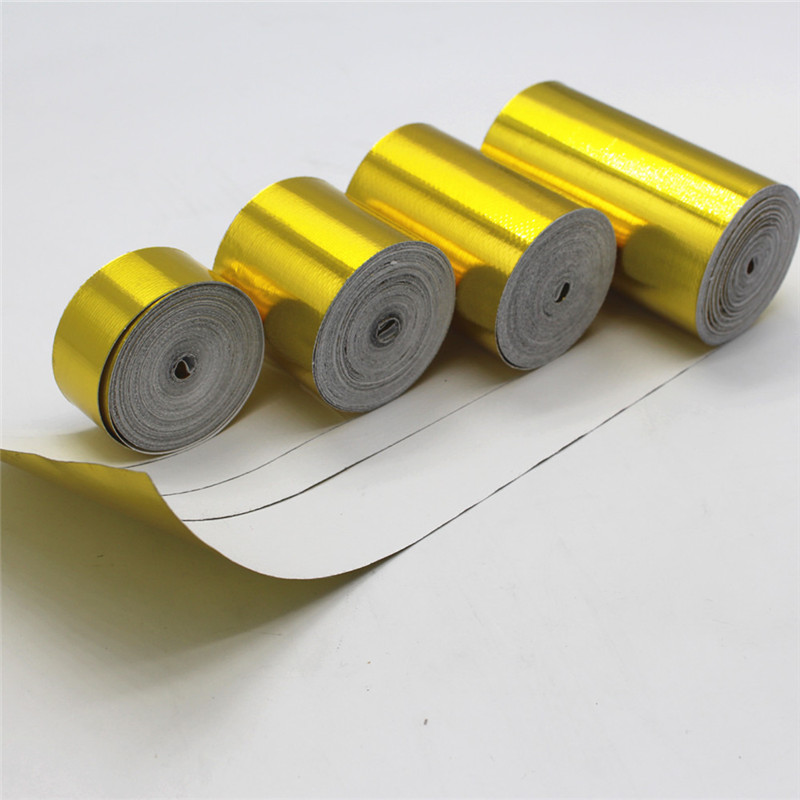

Film doré résistant à la chaleur est une solution légère et innovante, conçue pour résister aux variations de température extrêmes (-65 °F à +500 °F) dans les environnements exigeants. Fabriqué à partir d'un tissu de verre laminé en polymère polyamide métallisé et renforcé par un adhésif sensible à la pression haute température, ce matériau innovant allie durabilité et résistance thermique inégalée. Sa conception autocollante garantit une installation et un retrait aisés, ce qui le rend idéal pour un déploiement rapide dans les secteurs de l'aérospatiale, de l'automobile, de la marine et de l'industrie.

Principales caractéristiques et avantages

Résilience aux températures extrêmes

Maintient l'intégrité structurelle et l'adhérence grâce à des cycles thermiques rapides, du froid cryogénique à la chaleur torride.

La surface métallisée réfléchissante dévie la chaleur radiante, réduisant ainsi le transfert thermique jusqu'à 70 %.

Léger et polyvalent

40 % plus léger que les couvertures traditionnelles en fibre céramique, réduisant le poids du système dans les véhicules et les avions.

Le substrat flexible s'adapte parfaitement aux formes complexes (par exemple, composants d'échappement, carters de turbine).

Conçu pour la sécurité

Conforme aux normes d'inflammabilité FAR 25.853(a) pour les intérieurs aérospatiaux.

Zéro émission toxique en cas d'exposition à la chaleur, garantissant la sécurité de l'équipage et des passagers.

Adhérence de qualité industrielle

L'adhésif sensible à la pression adhère instantanément sans durcir, mais ne laisse aucun résidu lors du retrait.

Résiste aux vibrations jusqu'à 20G, parfait pour les applications à haute mobilité.

Cas d'application concrets

1. Gestion thermique du sport automobile

Une équipe de Formule E, championne du monde, a utilisé un film Gold Heat Resistant pour protéger les boîtiers de batteries en fibre de carbone des systèmes d'onduleurs adjacents à 250 °C. Ce film a permis de réduire la température de l'habitacle de 22 °C tout en gagnant 1,8 kg par rapport aux solutions traditionnelles, un atout essentiel pour une répartition du poids compétitive.

2. Mise à niveau du pare-feu aérospatial

Un constructeur d'avions régionaux a remplacé les panneaux pare-feu rigides en aluminium par notre revêtement dans les cuisines, obtenant ainsi une réduction de poids de 60 %. La résistance à froid du matériau à -65 °F a permis d'éviter la fragilité de l'adhésif lors des opérations en haute altitude.

3. Protection des processus industriels

Dans une usine de traitement chimique, des techniciens ont appliqué ce film pour protéger les conduits en PVC des jets de vapeur intermittents à 230 °C. Cette solution a permis de prolonger la durée de vie des conduits de 9 mois entre chaque remplacement, réduisant ainsi les coûts de maintenance de 18 000 $ par an.

Scénarios d'installation

Aéronef: Revêtements de nacelle moteur, compartiments d'unité auxiliaire de puissance (APU), pare-feu de toilettes

Automobile: Barrières thermiques pour batteries de véhicules électriques, boucliers thermiques pour turbocompresseurs, protection du câblage sous le capot

Marin: Cloisons de salle de générateur, isolation des tuyaux d'échappement dans les espaces confinés

Énergie: Gainage de tuyaux solaires thermiques, protection des équipements géothermiques

Supériorité technique

Les tests effectués par des tiers vérifient :

Résistance aux UV de 500 heures avec une dégradation de la réflectivité < 5 %

Efficacité du blindage EMI de 94 % à une fréquence de 1 GHz

Maintien de la résistance au pelage de 98 % après 50 cycles de choc thermique (-65 °F ↔ +500 °F)

Pourquoi choisir un film résistant à la chaleur doré ?

Après avoir testé 12 solutions thermiques pour notre prototype de rover lunaire, le Gold Wrap est le seul matériau à avoir résisté aux tests en chambre à vide avec des variations de température de 150 °C. C'est désormais notre norme pour les équipements extraterrestres.

– Dr Elena Voss, ingénieure principale, AstroDynamics R&D

Commande et personnalisation

Disponible en rouleaux (12" × 50', 24" × 25') ou en kits découpés pour les applications courantes (par exemple, les gabarits d'échappement Cummins X15). Demandez des certificats de résistance à la flamme et des rapports de tests ASTM pour les commandes groupées.

Améliorez votre stratégie thermique – Contactez notre équipe d’ingénierie dès aujourd’hui.