1. Barrière thermique aluminisée

Définition :Un matériau conçu pour réfléchir la chaleur radiante, généralement composé d'un substrat (par exemple, fibre de verre, polyester ou céramique) recouvert d'une couche d'aluminium.

Fonction La couche d'aluminium réfléchit jusqu'à 90 % de la chaleur radiante, tandis que le substrat assure isolation et durabilité. Il protège les composants des températures élevées en bloquant le transfert de chaleur.

Applications :

Automobile :Compartiments moteur, systèmes d'échappement.

Industriel :Machines, pipelines, systèmes CVC.

Construction : Greniers, toiture, isolation des murs.

Installation :Nécessite des fixations mécaniques (clips, vis) ou des rubans résistants à la chaleur.

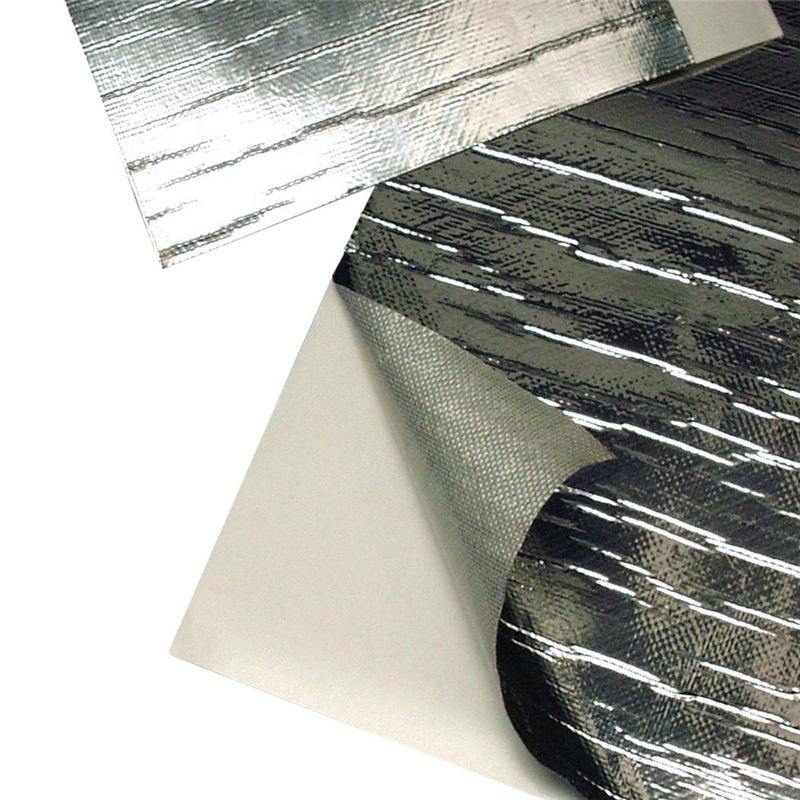

2. Barrière thermique aluminisée à dos adhésif

Définition :Similaire à la barrière standard mais comprend une couche adhésive résistante à la chaleur sur un côté pour une fixation facile.

Fonction : Combine réflexion de la chaleur et pose simplifiée. L'adhésif est conçu pour résister aux températures élevées sans se dégrader.

Applications :Idéal pour les surfaces où le perçage ou les fixations ne sont pas possibles, comme les pièces de moteur courbes, les boîtiers électroniques ou les conduits.

Installation :Application par pelage et collage ; nécessite des surfaces propres et sèches pour une adhérence optimale.

Considérations clés

Matériels Le choix du substrat (par exemple, fibre de verre pour la durabilité, polyester pour la flexibilité) affecte les performances. Le revêtement en aluminium peut être déposé en phase vapeur pour obtenir des couches fines et régulières.

Résistance à la température :Résiste généralement à des températures de -40 °F à 1 500 °F, selon le substrat et la qualité de l'adhésif.

Sécurité : Les supports comme la fibre de verre peuvent nécessiter le port de gants lors de leur manipulation. Les adhésifs doivent être non toxiques et peu émanants sous l'effet de la chaleur.

Avantages :

Une réflexion efficace de la chaleur réduit le stress thermique.

Léger et flexible pour une utilisation polyvalente.

La version adhésive permet de gagner du temps d'installation.

Limites :

L'adhésif peut se détériorer sous une chaleur ou une humidité extrême s'il n'est pas de haute qualité.

Coût plus élevé par rapport au papier aluminium de base.

Exemples :

Automobile : Boucliers thermiques à proximité des collecteurs d'échappement.

Usage domestique : Isolation réfléchissante dans les greniers.

Industriel : Enveloppage de fours ou chaudières industriels.

En résumé, les barrières thermiques aluminisées sont essentielles pour gérer la chaleur dans les environnements à haute température, la variante à dos adhésif offrant une commodité pour des applications spécifiques.